ARCTIC FOZZY

Active member

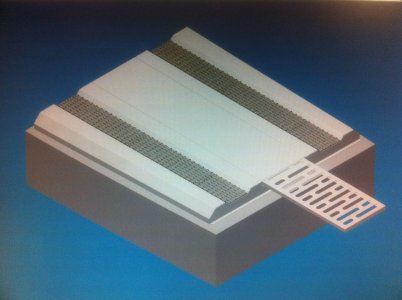

I am wondering if there would be any interest in a tonneau cover sled deck for 1/2 ton or 3/4 ton trucks.

I have designed one that is made for a newer dodge 1500. I have not built one yet but I am certain it would work very well.

-the deck would weight around 150 lbs or less.

-built out of aluminum

-easy rivet together assembly

-would hinge at the front with gas shocks to hold it up for access into the box just like a hard cover would.

-built in ramp for loading sled or quad.

-single place deck

-available for any truck

-super glides for skies or tires

-optional superclamp for tie down

This deck was designed for people that haul tools and other things for work that need them covered and to then function as a toy hauler deck on the weekends.

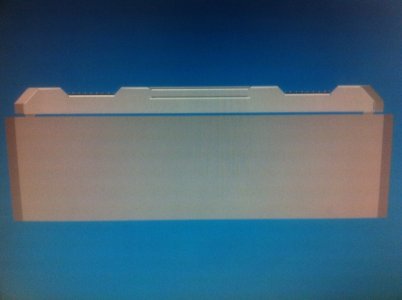

The attached pics shows the truck box and a short pull out extension for a track support, the pics do not show the ramp or the front headache rack.

The headache rack would just be like 6" tall to stop your skies from going through your windshield and to allow a pivot point for the deck.

The ramp would slide out on channels which would be mounted to the bottom of the deck and would lift up with the deck.

I am thinking this deck will be priced right around 2200.00 including superglides, gas shocks, headache rack, and loading ramp.

Any feedback would be great.

Thanks

brandon

I have designed one that is made for a newer dodge 1500. I have not built one yet but I am certain it would work very well.

-the deck would weight around 150 lbs or less.

-built out of aluminum

-easy rivet together assembly

-would hinge at the front with gas shocks to hold it up for access into the box just like a hard cover would.

-built in ramp for loading sled or quad.

-single place deck

-available for any truck

-super glides for skies or tires

-optional superclamp for tie down

This deck was designed for people that haul tools and other things for work that need them covered and to then function as a toy hauler deck on the weekends.

The attached pics shows the truck box and a short pull out extension for a track support, the pics do not show the ramp or the front headache rack.

The headache rack would just be like 6" tall to stop your skies from going through your windshield and to allow a pivot point for the deck.

The ramp would slide out on channels which would be mounted to the bottom of the deck and would lift up with the deck.

I am thinking this deck will be priced right around 2200.00 including superglides, gas shocks, headache rack, and loading ramp.

Any feedback would be great.

Thanks

brandon