NM

Boost It - Fuel your Boost

Had to start my own thread on this as I feel it is not my business to post in the Aero thread.

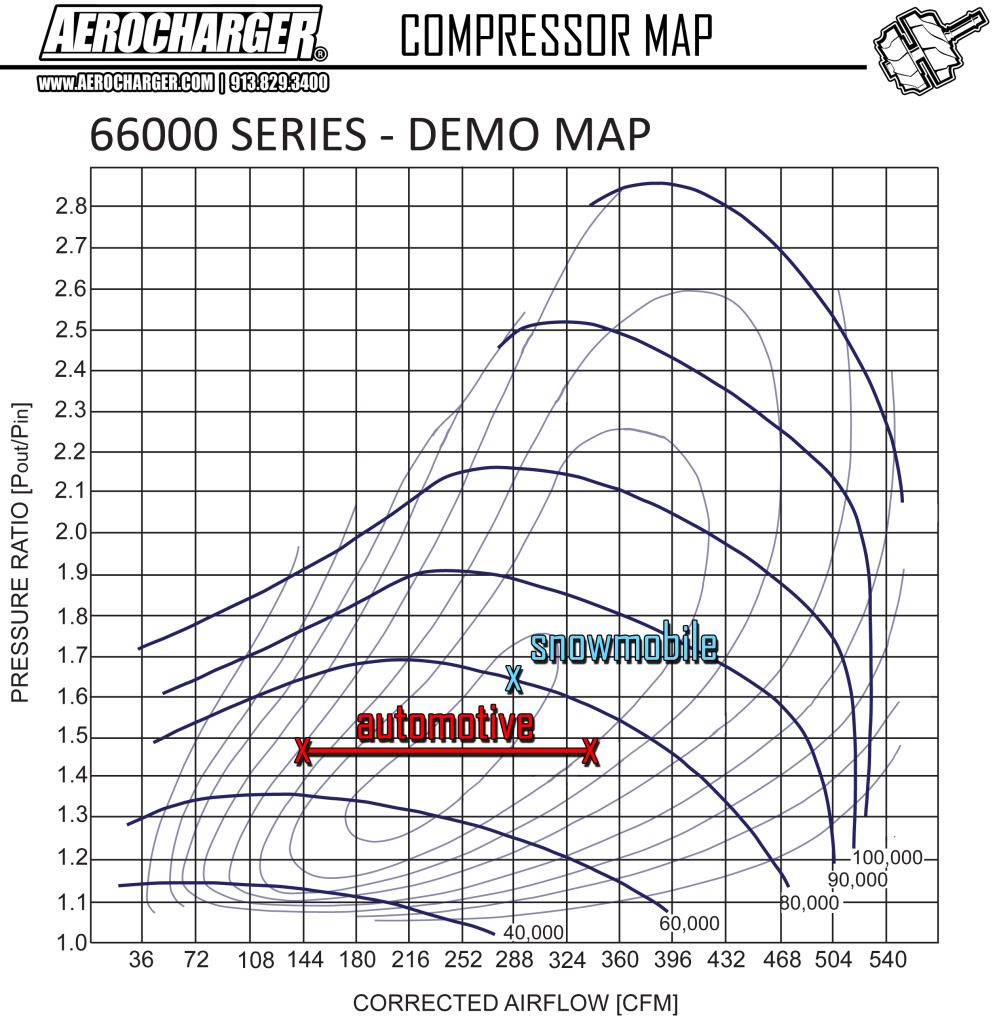

Who else thinks that Fred W should prove what he is saying. I want to see where a Aero turbo flows better at 8 lbs than Boondockers or TSS turbo at 12-13 lbs.

If this is fact...Aerocharger should have been using this factual information in their marketing efforts. I mean that would be something to brag about.

Lets see it Fred.

In my testing with a 2863 GTX vs an Aero 66, the GTX spooled faster and just kept pulling away. Both sleds at 8 lbs.

Who else thinks that Fred W should prove what he is saying. I want to see where a Aero turbo flows better at 8 lbs than Boondockers or TSS turbo at 12-13 lbs.

If this is fact...Aerocharger should have been using this factual information in their marketing efforts. I mean that would be something to brag about.

Lets see it Fred.

In my testing with a 2863 GTX vs an Aero 66, the GTX spooled faster and just kept pulling away. Both sleds at 8 lbs.