Ministik Man

Active VIP Member

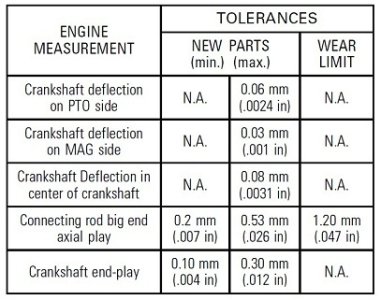

I have heard of the words CRANK RUN OUT

What is it?

What does it mean to the life of the motor?

Is it caused by bearings?

Thanks

What is it?

What does it mean to the life of the motor?

Is it caused by bearings?

Thanks