- Admin

- #21

- Joined

- Oct 20, 2006

- Messages

- 39,540

- Reaction score

- 14,738

- Location

- Edmonton Alberta, Canada

- Website

- www.sledbunnyracing.com

And once agian, you would be the man you know....lol....

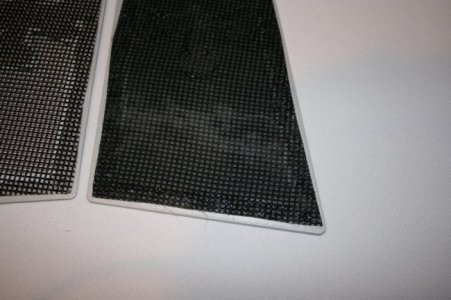

I used the extra heavy duty fiber glass pet screen from canadian tire. Its held up to some major abuse thus far for me.