Can anyone show me what the bolt head inside the brake rotor looks like? I have been working on getting it out for hours and I have come to the conclusion that my bolt head is sheared off. It's hard to tell what I'm looking at having never seen one before and that i'ts in there about two feet. Dimond drive won't come off w/o that bolt out. Secondly I looked at a seemingly identical diagram online of drive shaft (one an 05 one an 06) and the number labeling and prices were way different. My question is...Is the bolt different on an 05 compared to an 06? Thankyou very much in advance. Please help.

Can anyone show me what the bolt head inside the brake rotor looks like? I have been working on getting it out for hours and I have come to the conclusion that my bolt head is sheared off. It's hard to tell what I'm looking at having never seen one before and that i'ts in there about two feet. Dimond drive won't come off w/o that bolt out. Secondly I looked at a seemingly identical diagram online of drive shaft (one an 05 one an 06) and the number labeling and prices were way different. My question is...Is the bolt different on an 05 compared to an 06? Thankyou very much in advance. Please help.You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Diamond Drive removal and inspection tortural

- Thread starter dezmitchell

- Start date

- Thread starter

- #62

dezmitchell

Active VIP Member

05 and 06 were the same....I dont see a bolt head there so i would assume its sheared off. You should still be able to pull the DD off as long as there is no bolt head there shouldnt be so much holding it into the shaft. I will try to get a pic to compare after work.

Thankyou very much this is so frustrating becasue I just bought it and wanted to fix the speedo. Thanks to for the removal guide it is giving alot of people the knowledge to do this job themselves, **just a note too on the hidden bolt under the rubber.Tthose two hex nuts do not thread into the rubber and do not need to be taken ou,t the rubber is just wedged in there easy to remove with flat head.

As it turns out the bolt was sheared off at the the threads and this thing has been going w/o that bolt for along time. I took the diamond drive to the dealer and for some reason they extracted the boken bolt for me for free. I bought the "updated kit" ($78) that comes with the bolt rubber retainer some washers and two sleeves that make the bolt incappable from warping and bending under torque. Also an important note, the bolt on the 05 m7 is not the same as the 06. In 06 they corrected this problem and the bolt is shortened not sure about the details I have not actually seen an 06 just know what the dealer said. So if you have an 05 get the updated kit when this thing breaks check too that the bolt head is sticking out of the brake rotor like it should be. If its not then its broken, I would have not known it was broke if I hadnt had reason to pull off the dd. That was to replace the speedometer sensor. Which is also a problematic part the dealer said the sensor they sold me was also "updated" I guess time will tell.

Gunnertrav

New member

Anybody wanna comment on forward and back rotation on the input shaft. Everything looks an feels spanky in there but this movement seems a bit bad. When a guy locks up the brakes it would slap in there I would think. Pickups have some slop in em all the time but don't like it in a sled

Anybody wanna comment on forward and back rotation on the input shaft. Everything looks an feels spanky in there but this movement seems a bit bad. When a guy locks up the brakes it would slap in there I would think. Pickups have some slop in em all the time but don't like it in a sled

Others have commented about the total combined gear lash (wind-up) in a DD, with three separate gear mesh connections. Doesn't seem to cause problems. The synthetic oil, rubber drive belt, and rubber track should provide enough cushion.

Justin8485

Member

Newbie here, bringing this thread back up. Great thread btw!

I need your help, I have an 06 F7 and I have all 6 bolts mounting bolts off of the DD and

the bolt pulled out of the brake rotor. My DD is not coming off!! Even if I try to pry it and violently

wiggle it. Did I miss something, what else can I do???

I need your help, I have an 06 F7 and I have all 6 bolts mounting bolts off of the DD and

the bolt pulled out of the brake rotor. My DD is not coming off!! Even if I try to pry it and violently

wiggle it. Did I miss something, what else can I do???

Justin8485

Member

Is there another bolt inside where I took out

the long bolt from the brake rotor?

the long bolt from the brake rotor?

- Thread starter

- #72

dezmitchell

Active VIP Member

There is a bolt inside the shaft on the back side of the DD

There were 2 versions not sure what u have but

1. Long bolt (over 1 foot) u take off and see the head of the bolt on the center of the brake rotor

2. Short bolt inside of the hollow shaft your rotor is on u need about a foot worth of extensions if i remember correctly its a 5/8 bolt but dont quote me its been a long time.

Dont get in there and pry like mad there may be some rust holding the shaft to the splines of the DD. SOMETHING is still connected have a beer and take a good long look and maske sure u got EVERY bolt before trying other options including spraying penitrating oil all around where the splines on the DD connect with the drive shaft.

There were 2 versions not sure what u have but

1. Long bolt (over 1 foot) u take off and see the head of the bolt on the center of the brake rotor

2. Short bolt inside of the hollow shaft your rotor is on u need about a foot worth of extensions if i remember correctly its a 5/8 bolt but dont quote me its been a long time.

Dont get in there and pry like mad there may be some rust holding the shaft to the splines of the DD. SOMETHING is still connected have a beer and take a good long look and maske sure u got EVERY bolt before trying other options including spraying penitrating oil all around where the splines on the DD connect with the drive shaft.

Justin8485

Member

Thanks! I have the long bolt going through the brake rotor. Ok, so when you say "there is a bolt inside the shaft on the back side of the DD".... can you describe more in detail where I cab find this bolt or by chance have a picture? I've never done this before and this thread inspired me to get at it myself.

CamoKVF700

Active VIP Member

Re: Step by step DD removal and inspection guide WITH PICS

Thank you. Great thread.

Thank you. Great thread.

Justin8485

Member

Re: Step by step DD removal and inspection guide WITH PICS

Success! I got it off and split the cases. everything seemed alright with a sled that has 4500miles! spins nice and smooth. The trick to getting it off the drive shaft was to thread the brake rotor bolt a little bit back in and gently tap it forwards. doing this was very easy! its to bad I didn't try it first!

Success! I got it off and split the cases. everything seemed alright with a sled that has 4500miles! spins nice and smooth. The trick to getting it off the drive shaft was to thread the brake rotor bolt a little bit back in and gently tap it forwards. doing this was very easy! its to bad I didn't try it first!

mallard d69

Active VIP Member

Re: Step by step DD removal and inspection guide WITH PICS

another trick when you have a sticky DD that does not want to come out and you may still yet have to do this anyway to re-install it is to loosen the track. I did this when I did my DD and it made things a lot easier

another trick when you have a sticky DD that does not want to come out and you may still yet have to do this anyway to re-install it is to loosen the track. I did this when I did my DD and it made things a lot easier

meierjn

Active VIP Member

Re: Step by step DD removal and inspection guide WITH PICS

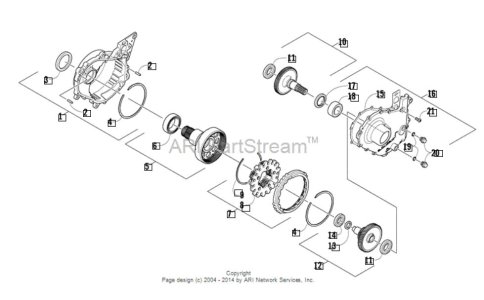

Great thread. But I am a bit confused... I have a 2011 HCR. Which is the 6203 bearing in the diagram that should be replaced? There are several threads about replacing the 6203 with a 5203 or a 4203 (if you can find one) and even a newer 3203. I currently have my DD sitting on the bench. The sled has about 400 miles on it and would like to tackle the job while the DD is out. Thanks!

Great thread. But I am a bit confused... I have a 2011 HCR. Which is the 6203 bearing in the diagram that should be replaced? There are several threads about replacing the 6203 with a 5203 or a 4203 (if you can find one) and even a newer 3203. I currently have my DD sitting on the bench. The sled has about 400 miles on it and would like to tackle the job while the DD is out. Thanks!

Attachments

Last edited:

Info about my 2011 HCR, be sure to read post #118 because my HCR had a gross mis-match between the track drive shaft and aluminum tunnel, which causes the 6203 bearing to fail. https://www.snowandmud.com/arctic-c...-drive-bearing-upgrade-thread-lots-47974.html Also: https://www.snowandmud.com/arctic-cat-m-series-456/2011-m8-new-owners-check-your-70878.html

From a discussion on SnoWest a few days ago (http://www.snowest.com/forum/showthread.php?t=381080): A 3203 bearing to you and me is dimensionally identical to a 5203 (ID, OD, width). The difference is the 3203 is a newer design with extremely high quality bearing steel with much reduced impurities and better grain structure, better heat treatment for improved dimensional stability (up to 300 °F), internal geometry design changes that are less sensitive to axial overloading, races manufactured to P6 running accuracy, ball uniformity manufactured to one ISO grade better than SKF 5203 (several grades better as compared to other brands) which improves running accuracy at high speeds (reducing noise and operating temperature), improved Polyamide (Nylon) cage to better withstand high accelerations. Those changes resulted in lab-tested load-carrying performance improvement, increased durability (similar axial wear at 40,000 hours vs. 1000 hours), higher reliability, and longer service life (tested at double vs. SKF 5203, more for other brands).

In my opinion, an SKF 3203 ATN9/C3 in a critical application like this, in a $800 DD, in a $10,000 sled, which could ruin a cool ride - is worth the extra $20 cost vs. a Chinese Peer (BDX) 5203. You can purchase one for about $35 at a local industrial power transmission store, ebay or amazon. Some related good discussions:

sealed vs unsealed:

Is this DD oil normal after 500kms / 300 miles? - SnoWest Snowmobile Forum

4203 bearing in 2010 M8 update - SnoWest Snowmobile Forum

3203 vs 5203 bearings:

Should I changed DD fluid? - SnoWest Snowmobile Forum

Hope those help. Good luck!

From a discussion on SnoWest a few days ago (http://www.snowest.com/forum/showthread.php?t=381080): A 3203 bearing to you and me is dimensionally identical to a 5203 (ID, OD, width). The difference is the 3203 is a newer design with extremely high quality bearing steel with much reduced impurities and better grain structure, better heat treatment for improved dimensional stability (up to 300 °F), internal geometry design changes that are less sensitive to axial overloading, races manufactured to P6 running accuracy, ball uniformity manufactured to one ISO grade better than SKF 5203 (several grades better as compared to other brands) which improves running accuracy at high speeds (reducing noise and operating temperature), improved Polyamide (Nylon) cage to better withstand high accelerations. Those changes resulted in lab-tested load-carrying performance improvement, increased durability (similar axial wear at 40,000 hours vs. 1000 hours), higher reliability, and longer service life (tested at double vs. SKF 5203, more for other brands).

In my opinion, an SKF 3203 ATN9/C3 in a critical application like this, in a $800 DD, in a $10,000 sled, which could ruin a cool ride - is worth the extra $20 cost vs. a Chinese Peer (BDX) 5203. You can purchase one for about $35 at a local industrial power transmission store, ebay or amazon. Some related good discussions:

sealed vs unsealed:

Is this DD oil normal after 500kms / 300 miles? - SnoWest Snowmobile Forum

4203 bearing in 2010 M8 update - SnoWest Snowmobile Forum

3203 vs 5203 bearings:

Should I changed DD fluid? - SnoWest Snowmobile Forum

Hope those help. Good luck!

Last edited:

Meierjn : i believe it is #14 on the parts explosion. I have been researching this too, as i have an '11 as well with 1500 miles, no problems yet, but don't want to gamble with a known issue on these bearings.

meierjn

Active VIP Member

Info about my 2011 HCR, be sure to read post #118 because my HCR had a gross mis-match between the track drive shaft and aluminum tunnel, which causes the 6203 bearing to fail. https://www.snowandmud.com/arctic-c...-drive-bearing-upgrade-thread-lots-47974.html Also: https://www.snowandmud.com/arctic-cat-m-series-456/2011-m8-new-owners-check-your-70878.html

From a discussion on SnoWest a few days ago (2010 diamond drive bearing - SnoWest Snowmobile Forum A 3203 bearing to you and me is dimensionally identical to a 5203 (ID, OD, width). The difference is the 3203 is a newer design with extremely high quality bearing steel with much reduced impurities and better grain structure, better heat treatment for improved dimensional stability (up to 300 °F), internal geometry design changes that are less sensitive to axial overloading, races manufactured to P6 running accuracy, ball uniformity manufactured to one ISO grade better than SKF 5203 (several grades better as compared to other brands) which improves running accuracy at high speeds (reducing noise and operating temperature), improved Polyamide (Nylon) cage to better withstand high accelerations. Those changes resulted in lab-tested load-carrying performance improvement, increased durability (similar axial wear at 40,000 hours vs. 1000 hours), higher reliability, and longer service life (tested at double vs. SKF 5203, more for other brands).

In my opinion, an SKF 3203 ATN9/C3 in a critical application like this, in $800 DD, in a $10,000 sled, which could ruin a cool ride - is worth the extra $20 cost vs. a Chinese Peer (BDX) 5203. You can purchase one for about $35 at a local industrial power transmission store, ebay or amazon. Some good discussions:

sealed vs unsealed:

Is this DD oil normal after 500kms / 300 miles? - SnoWest Snowmobile Forum

4203 bearing in 2010 M8 update - SnoWest Snowmobile Forum

3203 vs 5203 bearings:

Should I changed DD fluid? - SnoWest Snowmobile Forum

Hope those help. Good luck!

Thanks for the info. I also read if you go to the 5203 you have to grind some shaft down a bit to make up for the larger bearing size. If the 3203 is the same size as the 5203 I am assuming you would have to machine the shaft down as well?

Also, in the diagram above which bearing is it?

Similar threads

- Replies

- 119

- Views

- 3K