nuggetau

Member

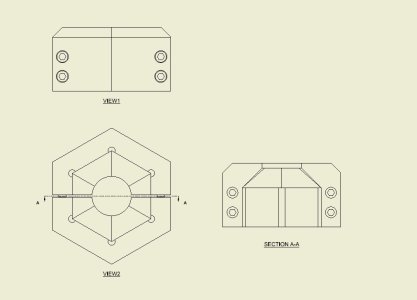

I will pay $300 to anyone who can make me a CNC billet 2 piece clamp that is 2 inches wide on the extrusion( full contact on all sides with 2 recessed stainless bolts on each side) that curves out and encloses the steel shaft cap. It must be a close tolerance fit, especially on the steel cap.

I want nothing to do with the current clamps as they do not address the reason the shafts are failing. The shaft has tension on it from multiple sources, track tension, absorbing impacts to the approach angle, sudden braking, etc. Those forces pull back and forth on the center of the shaft which causes the tinniest of separations, these forces are trying to lengthen the shaft which cause the joint to pull apart. Over hundreds of thousands of revolutions that tiny separation gets big enough that the joint binds, combined with the rotational force it then tears out the sidewall of the extrusion.

The current "fix" does absolutely nothing to address the cause of the failure!!! It will extend the time before the extrusion fails, that is all! But in reinforcing the weak tear point(extrusion), you now will just transfer an even greater force somewhere else once the joint gets sloppy enough to fail. More than likely it will be the casting supporting the steel shaft.

There are really only 2 solutions, buy a steel shaft which will cost you $200-500 (if you can find one) or support the joint in the existing shaft so that it can't separate and fail. The existing clamp does not support the joint, it only helps to prolong the tear out.

My offer is genuine, if you can make a close tolerance clamp as I described I will buy it! This $300 fix would be cheaper and easier that trying to find a steel shaft with the right drivers, bearings, and that has little run out which could cause problems with the Quick drive.

I want nothing to do with the current clamps as they do not address the reason the shafts are failing. The shaft has tension on it from multiple sources, track tension, absorbing impacts to the approach angle, sudden braking, etc. Those forces pull back and forth on the center of the shaft which causes the tinniest of separations, these forces are trying to lengthen the shaft which cause the joint to pull apart. Over hundreds of thousands of revolutions that tiny separation gets big enough that the joint binds, combined with the rotational force it then tears out the sidewall of the extrusion.

The current "fix" does absolutely nothing to address the cause of the failure!!! It will extend the time before the extrusion fails, that is all! But in reinforcing the weak tear point(extrusion), you now will just transfer an even greater force somewhere else once the joint gets sloppy enough to fail. More than likely it will be the casting supporting the steel shaft.

There are really only 2 solutions, buy a steel shaft which will cost you $200-500 (if you can find one) or support the joint in the existing shaft so that it can't separate and fail. The existing clamp does not support the joint, it only helps to prolong the tear out.

My offer is genuine, if you can make a close tolerance clamp as I described I will buy it! This $300 fix would be cheaper and easier that trying to find a steel shaft with the right drivers, bearings, and that has little run out which could cause problems with the Quick drive.