Dynamo^Joe

Active VIP Member

Chris) Joe was just wondering if you could start up a thread sharing the clutch changes for the 2021 turbo sleds and how it will effect performance VS clutch kits over the 2020 models. As well it seems there is an array of new clutch arms, what does all that mean for users and clutch kit builders.

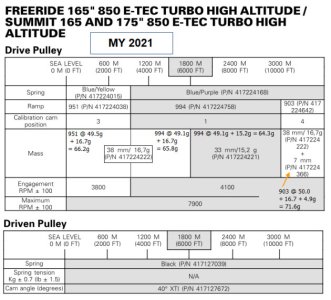

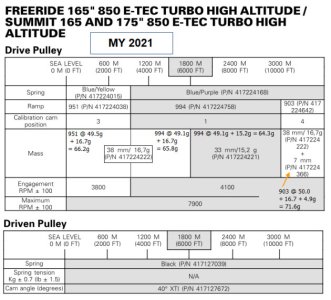

Joe) ok lets look at 20.5 vs 21 specs first.

2020.5 x 850T

Ramp-984, Pivot 38mm @ 16.7g, Cam 40 deg. Clutch Spring 150-350. Black Spring 160/303

Settings

Clicker 1; 0~8000f (165hp)

Clicker 2; 8000~9000ft (160hp)

Clicker 3; 9000~10000ft (155hp)

Clicker 4; 10000~11000ft (150hp)

Clicker 5; 11000~12000ft (145hp)

………………..seems pretty simple eh? If you have an overrev problem in a pull, really, it’s as simple as getting a spacer weight to put on the pivot bolt to correct engines speed.

Below is MY (model year) 2021.

I sorted out the grams for the 951, 994 and 903 on that spec sheet. (Ramp# + applicable pivot bolt)

Chris) clutch changes for the 2021 turbo sleds and how it will effect performance VS clutch kits over the 2020 models

Joe) nothing really. Regardless of 20.5 or 21 model, still has the same “convertor”, the same secondary clutch settings. They both have a 40 helix and 160/303 secondary spring.

I have a secondary force calculator (and its not the team one) for skidoo QRS secondary clutches.

When you apply a torque of 115 pounds from the 850 engine, the secondary converts estimated 856 pounds on the side of the belt at the start of the shift off of engagement to move the sled and 520 pounds at 1:1 clutch ratio. (belt at 7/8” from the rim of the primary clutch).

Ok with that being said…You can put a 951, 994, 903, 984, 990, 968, 967, 971, this guys clutch weight, that guys clutch weight and in the end, regardless of the weight of it, the secondary still will convert….

…….856 pounds on the side of the belt at the start of the shift off of engagement to move the sled and 520 pounds at 1:1 clutch ratio [until you change the spring force and/or helix angle(s)]

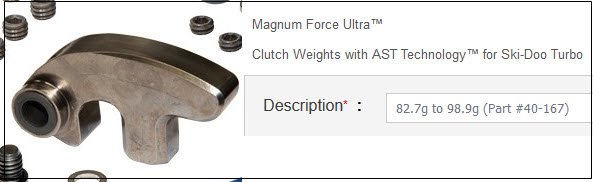

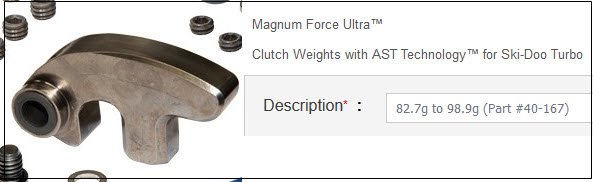

Here is an example of this or that guys clutch weight.

https://www.silberturbos.com/products/ski-doo-850-gen4-turbo-ramps

Silber has a 59.3 gram clutch weight. Hereinafter lets call it the STR (silber turbo ramp)

If you put that in with the standard pivots, 16.7 or 15.2 or (16.7+4.9 spacer) then you will underrev and have to clicker up to get correct engine speed. How much rpms would you lose by putting that weight in?

Lets do the 6000~10000 pivot setting.

STR @ 59.3 grams + 15.2 grams = 74.5 grams. Wait, the requirement for correct engine speed is 64.3 grams. (go back up to look at the brp spec)

Estimate engine speed loss from being over grams.

74.5g – 64.3 grams = 10.2 grams. Yeesh, at 1 gram = 200 rpms then you are looking at a 2000 rpms loss (in theory)

Q) How do we lose 10.2 grams? A) lighter pivot bolt and possible higher clicker number.

There is a 8.9 gram titanium bolt (25mm)

Then…

STR @ 59.3 grams + 8.9TI gram pivot = 68.2 grams. But we need to get into the 64.3 grams. 4 grams too heavy. There is a clicker adjustment we can do. IF a clicker can change 200 rpms, THEN have to change 4 clicker numbers.

Go from clicker 1 to 5 and that should be close to get 7900 rpms again.

Then…

Here is the complete 994 ramp cam arm assembly complete with factory parts including clicker adjuster. The overall weight is 85.7 grams.

Now lets look at a weight eliminating the clicker.

With this 82.7g SLP weight, you need to add more grams for it to be even with the BRP assembly @ 85.7 grams.

85.7g(BRP) – 82.7g(empty SLP) = 3 grams. You will be adding 3 grams of whatever setscrews or washers to make the ramp weigh the same as stock BRP @ 85.7 in clicker #1.

You go run the stock BRP weight at 85.7 grams in clicker 1. (has clicker adjustment)

You go run the STR weight at 89.5 grams in clicker 5 (has clicker adjustment)

You go run the SLP weight at 85.7 grams (no clicker adjustment)

….all 3 (in theory) should run at estimated 7900 rpms.

………and; when you apply a torque of 115 pounds from the 850 engine, the secondary converts 856 pounds on the side of the belt at the start of the shift off of engagement to move the sled and 520 pounds at 1:1 clutch ratio. (belt at 7/8” from the rim of the primary clutch) regardless of...

….all 3 (in theory) should run at estimated 7900 rpms but you loop right back to “856 pounds to 520 pounds” because no matter how you push from the primary clutch with Moe or Larry or Curley’s ramps, you still convert “856 to 520” to the track from the secondary clutch.

This primary clutch weight over here, pulling on the belt with that secondary settings over there, is still going to produce 7900 rpms.

IF the weight is lighter, THEN you'll see more than 7900

IF the weight is heavier, THEN you'll see less than 7900

...the secondary settings are constant, you havent changed anything, regardless of 20.5 or 21.

Secondary clutch

The average secondary clutch setup is estimated 60% efficient. IF there is 160hp, THEN the secondary clutch converts estimated 96hp (40 helix + black spring)

You can put Moe/Larry/Curly's ramp or use whatever BRP ramp in your primary clutch.

A logic statement....

IF I fiddle with my secondary clutch settings to raise my efficiency from 60% to 64% by a different helix and/or spring force and optimize gearing, THEN no matter what you run in your primary; "me", with a stock ramp and correct pivot bolt weight matched to the secondary to achieve 7900, "you make the rules" and ill show up to race you.

hope that was alright...my eyes are buggy now.

Joe) ok lets look at 20.5 vs 21 specs first.

2020.5 x 850T

Ramp-984, Pivot 38mm @ 16.7g, Cam 40 deg. Clutch Spring 150-350. Black Spring 160/303

Settings

Clicker 1; 0~8000f (165hp)

Clicker 2; 8000~9000ft (160hp)

Clicker 3; 9000~10000ft (155hp)

Clicker 4; 10000~11000ft (150hp)

Clicker 5; 11000~12000ft (145hp)

………………..seems pretty simple eh? If you have an overrev problem in a pull, really, it’s as simple as getting a spacer weight to put on the pivot bolt to correct engines speed.

- Law: IF need lower rpms, THEN add flyweight.

- Rule of thumb; 0.5grams = estimated 100 rpms change. 1.0 grams = estimated 200 rpms change.

Below is MY (model year) 2021.

I sorted out the grams for the 951, 994 and 903 on that spec sheet. (Ramp# + applicable pivot bolt)

Chris) clutch changes for the 2021 turbo sleds and how it will effect performance VS clutch kits over the 2020 models

Joe) nothing really. Regardless of 20.5 or 21 model, still has the same “convertor”, the same secondary clutch settings. They both have a 40 helix and 160/303 secondary spring.

I have a secondary force calculator (and its not the team one) for skidoo QRS secondary clutches.

When you apply a torque of 115 pounds from the 850 engine, the secondary converts estimated 856 pounds on the side of the belt at the start of the shift off of engagement to move the sled and 520 pounds at 1:1 clutch ratio. (belt at 7/8” from the rim of the primary clutch).

Ok with that being said…You can put a 951, 994, 903, 984, 990, 968, 967, 971, this guys clutch weight, that guys clutch weight and in the end, regardless of the weight of it, the secondary still will convert….

…….856 pounds on the side of the belt at the start of the shift off of engagement to move the sled and 520 pounds at 1:1 clutch ratio [until you change the spring force and/or helix angle(s)]

Here is an example of this or that guys clutch weight.

https://www.silberturbos.com/products/ski-doo-850-gen4-turbo-ramps

Silber has a 59.3 gram clutch weight. Hereinafter lets call it the STR (silber turbo ramp)

If you put that in with the standard pivots, 16.7 or 15.2 or (16.7+4.9 spacer) then you will underrev and have to clicker up to get correct engine speed. How much rpms would you lose by putting that weight in?

Lets do the 6000~10000 pivot setting.

STR @ 59.3 grams + 15.2 grams = 74.5 grams. Wait, the requirement for correct engine speed is 64.3 grams. (go back up to look at the brp spec)

Estimate engine speed loss from being over grams.

74.5g – 64.3 grams = 10.2 grams. Yeesh, at 1 gram = 200 rpms then you are looking at a 2000 rpms loss (in theory)

Q) How do we lose 10.2 grams? A) lighter pivot bolt and possible higher clicker number.

There is a 8.9 gram titanium bolt (25mm)

Then…

STR @ 59.3 grams + 8.9TI gram pivot = 68.2 grams. But we need to get into the 64.3 grams. 4 grams too heavy. There is a clicker adjustment we can do. IF a clicker can change 200 rpms, THEN have to change 4 clicker numbers.

Go from clicker 1 to 5 and that should be close to get 7900 rpms again.

Then…

Here is the complete 994 ramp cam arm assembly complete with factory parts including clicker adjuster. The overall weight is 85.7 grams.

Now lets look at a weight eliminating the clicker.

With this 82.7g SLP weight, you need to add more grams for it to be even with the BRP assembly @ 85.7 grams.

85.7g(BRP) – 82.7g(empty SLP) = 3 grams. You will be adding 3 grams of whatever setscrews or washers to make the ramp weigh the same as stock BRP @ 85.7 in clicker #1.

You go run the stock BRP weight at 85.7 grams in clicker 1. (has clicker adjustment)

You go run the STR weight at 89.5 grams in clicker 5 (has clicker adjustment)

You go run the SLP weight at 85.7 grams (no clicker adjustment)

….all 3 (in theory) should run at estimated 7900 rpms.

………and; when you apply a torque of 115 pounds from the 850 engine, the secondary converts 856 pounds on the side of the belt at the start of the shift off of engagement to move the sled and 520 pounds at 1:1 clutch ratio. (belt at 7/8” from the rim of the primary clutch) regardless of...

- BRP weight at 85.7 grams in clicker 1. (has clicker assembly adjustment) [makes 7900 full throttle]

- STR weight at 89.5 grams in clicker 5 (has clicker assembly adjustment) [makes 7900 full throttle]

- SLP weight at 85.7 grams (no clicker assembly adjustment) [makes 7900 full throttle]

….all 3 (in theory) should run at estimated 7900 rpms but you loop right back to “856 pounds to 520 pounds” because no matter how you push from the primary clutch with Moe or Larry or Curley’s ramps, you still convert “856 to 520” to the track from the secondary clutch.

This primary clutch weight over here, pulling on the belt with that secondary settings over there, is still going to produce 7900 rpms.

IF the weight is lighter, THEN you'll see more than 7900

IF the weight is heavier, THEN you'll see less than 7900

...the secondary settings are constant, you havent changed anything, regardless of 20.5 or 21.

Secondary clutch

The average secondary clutch setup is estimated 60% efficient. IF there is 160hp, THEN the secondary clutch converts estimated 96hp (40 helix + black spring)

You can put Moe/Larry/Curly's ramp or use whatever BRP ramp in your primary clutch.

A logic statement....

IF I fiddle with my secondary clutch settings to raise my efficiency from 60% to 64% by a different helix and/or spring force and optimize gearing, THEN no matter what you run in your primary; "me", with a stock ramp and correct pivot bolt weight matched to the secondary to achieve 7900, "you make the rules" and ill show up to race you.

hope that was alright...my eyes are buggy now.

Last edited: