ippielb

Active VIP Member

- Joined

- Mar 4, 2011

- Messages

- 1,912

- Reaction score

- 3,278

- Location

- SE Saskatchewan

- Website

- www.youtube.com

Just curious how many people do DIY sled mods. Not anything store bought. I'm talking grinding, cutting, moving, drilling, parts and pieces on your sled to get an improvement. Maybe even robbing parts off of another model of sled to make it work better. Post a picture of your mod, improvement, and sled. Maybe get a ball rolling on little improvements for others.

2010 Snopro 500 mod sled

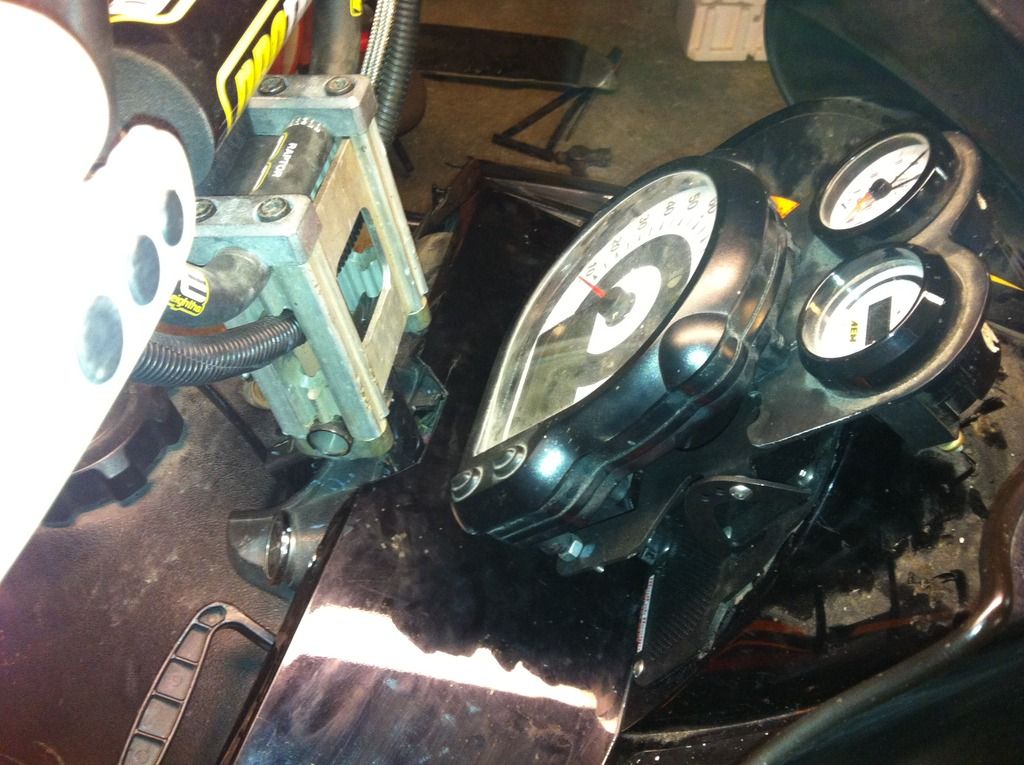

Mine isn't much, just narrow a arms, kept the longer shocks for added ground clearance, and put on proclimb spindles that are taller and narrower, taller to keep upper balljoint angle, and skinny to not act like an anchor like my 3" wide Snopro spindles. The arms had 2" cut out of each tube, and then slipped another tube inside to weld to for strength. The spindles needed to have some material taken off at the lower ball joint so it would clear it, since the Snopro ball joints have a larger outer diameter. The taper on the upper and lower ball joints is the same. I also did the 2013 tie rod hole on the spindle to get a tighter turning radius.

Heres the template I used on the spindles, made life easy to do that mod.

2013 Spindle Template for 2012 Sleds - SnoWest Snowmobile Forum

The cooler was mounted in the rear of the sled with cooling rails going through the tunnel, I removed the cooler from the rear and mounted it underneath the gas tank to hopefully cut down on ice, and to prevent it from breaking the cooling rails if I fold my tunnel again. The cooler is the rear cooler from an 09-11 m8 so it has the tip on the very end where the hoses connect. I needed the cooler to bend upwards to fit my tunnel at the jack shaft, so I put it in my press and used a couple pieces of hardwood as braces, and heated the cooler up, pressed down, and straightened it out. Then pushed it a little past straight so it would bend up with the tunnel giving me adequate clearance. I used pop rivets to hold the cooler up, and was afraid of the gas tank wiggling it might wear on the tank, so I put silicone on top of each rivet and around it to give it a bigger surface area and a buffer between the two. I let the silicone set and dry before I put the tank on so it wouldn't squish out.

2010 Snopro 500 mod sled

Mine isn't much, just narrow a arms, kept the longer shocks for added ground clearance, and put on proclimb spindles that are taller and narrower, taller to keep upper balljoint angle, and skinny to not act like an anchor like my 3" wide Snopro spindles. The arms had 2" cut out of each tube, and then slipped another tube inside to weld to for strength. The spindles needed to have some material taken off at the lower ball joint so it would clear it, since the Snopro ball joints have a larger outer diameter. The taper on the upper and lower ball joints is the same. I also did the 2013 tie rod hole on the spindle to get a tighter turning radius.

Heres the template I used on the spindles, made life easy to do that mod.

2013 Spindle Template for 2012 Sleds - SnoWest Snowmobile Forum

The cooler was mounted in the rear of the sled with cooling rails going through the tunnel, I removed the cooler from the rear and mounted it underneath the gas tank to hopefully cut down on ice, and to prevent it from breaking the cooling rails if I fold my tunnel again. The cooler is the rear cooler from an 09-11 m8 so it has the tip on the very end where the hoses connect. I needed the cooler to bend upwards to fit my tunnel at the jack shaft, so I put it in my press and used a couple pieces of hardwood as braces, and heated the cooler up, pressed down, and straightened it out. Then pushed it a little past straight so it would bend up with the tunnel giving me adequate clearance. I used pop rivets to hold the cooler up, and was afraid of the gas tank wiggling it might wear on the tank, so I put silicone on top of each rivet and around it to give it a bigger surface area and a buffer between the two. I let the silicone set and dry before I put the tank on so it wouldn't squish out.

Last edited: